MonoPan® – versatile joining technique

MonoPan® could be fastened by different technologies:

Mechanical joints

Fastening by gluing

Fastening by thermal welding

Joints with blind rivets

Blind rivets, especially butterfly rivets for crimping, are extremely suitable for fastening MonoPan® connections. Due to the high elongation at break of polypropylene and the strength of the glass fibres even high loads can be applied into the panel skins. Since these skins are thermally fused with the honeycomb cores the loads attached by the rivets will not lead to delamination.

Rivets do not only offer good load-bearing properties but can also be processed quickly and easily. A selection of suitable rivet types is listed in our datasheet for mechanical joints.

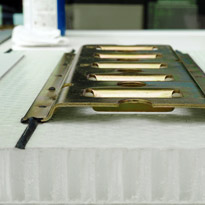

Bolted joints with screws

For safe and strong bolted joints with MonoPan® it is recommended to use MonoLock sleeves in combination with self-cutting screws. Thus MonoPan® could be connected safely with aluminium or steel girders and support bars. The connection is provided by a self-cutting screw and a thermoplastic MonoLock sleeve. The thread of the screw is anchored into the steel girder. The MonoLock sleeve is transferring the load into the MonoPan® panel by its strong clamping into the bottom surface. Additionally, the flange is crimped into the top surface and providing a flat top.

Bonding connections with MonoPan®

Due to the low surface energy and resulting low adhesion bonding onto MonoPan® requires special preparation, e.g. with a suitable plastic primer. There are various different gluing systems available for connections with MonoPan®.

Adhesive Bonding to MonoPan (PDF)

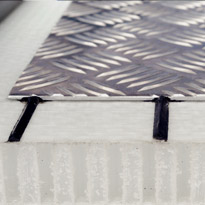

Thermally fused connections by thermoplastic welding

Thermoplastic materials such as MonoPan® offer a special feature for lasting connections by thermoplastic welding. One way to provide the connection is by using electrically heated welding profiles or wires.

Another possible way is to use thermal extrusion welding, especially in case of higher requirements on the impermeability of the connection and proper closing of grooves.